Creating the Factory of the Future with 4.0 Solutions

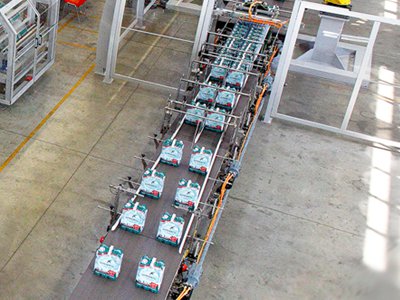

Within the manufacturing industry, the complexity of production plants is steadily rising due to increasing product variances, product complexity, and pressures for production efficiency. Production systems must therefore now evolve rapidly and operate optimally, creating challenges for larger Industries and serious problems for SMEs without the needed expertise or sufficient resources to adapt new technical possibilities.

To meet these challenges, the European research and innovation project IMPROVE has developed novel data-based solutions to enhance machine reliability and efficiency. Innovative tools in the fields of simulation & optimization, condition monitoring, alarm management, and quality prediction provide manufacturers with a human machine interface (HMI) and decision support system (DSS) to ensure best possible user support.

Follow IMPROVE on ResearchGate Follow IMPROVE on LinkedInLatest News

-

Successful end of the IMPROVE project

After three years of intense research and lively and inspiring collaboration, the IMPROVE project... -

IMPROVE interview clip: A look behind the scenes

As the IMPROVE project is coming to an end, the consortium has released a short video clip...

“Our mission within IMPROVE is to provide innovative solutions for small and medium-sized enterprises in Europe to enhance the productivity of automated manufacturing and to facilitate machine operation. With our tools, we help companies be better prepared for international competition in times of Industry 4.0.”

CPS involve rapid communication and feedback control of physical processes through intelligence mechanisms which coordinate interactions with networked computational elements.

Learn moreThe vFoF is a cyber replication of the physical factory which greatly extends manual capabilities for tasks such as optimization, simulation, condition monitoring and diagnosis.

Learn moreIMPROVE technologies are tested in powerful laboratory demonstrators and industrial production plants enabling verification of results and adaptation to real life requirements.

Learn more